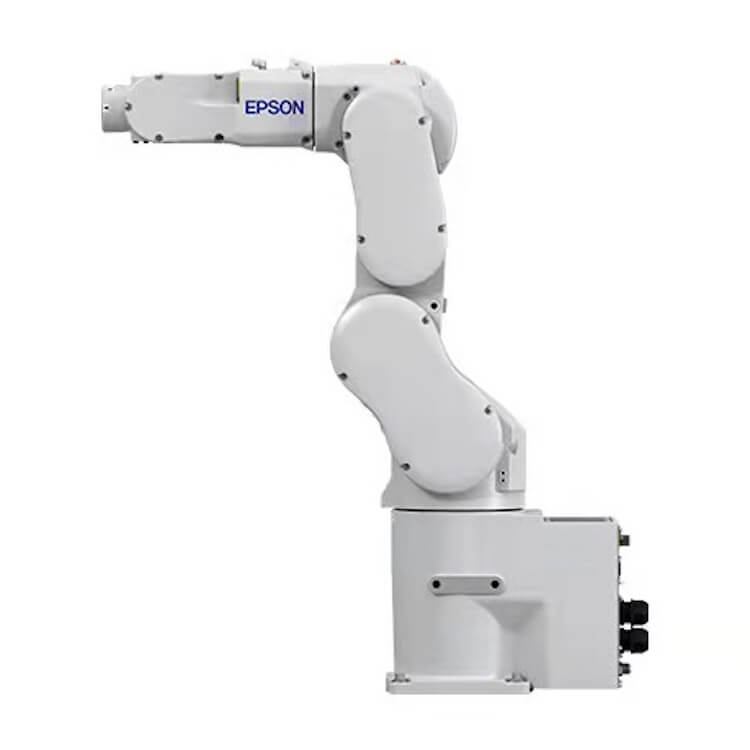

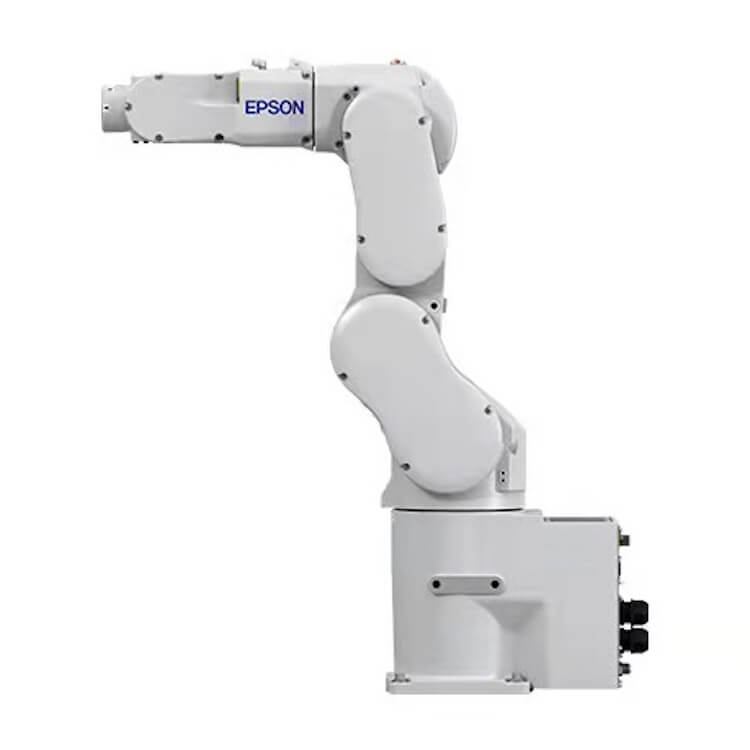

Epson C8L long-distance 6-axis robot has high performance and wider range of motion, while maintaining its unique slim linear package. The load is as high as 8kg, it can enter the narrow space, complete a variety of different medium-sized six axis work, and occupies a small area. Like the Epson C4 robot, the c8l design includes a compact wrist pitch and slim body elbows. The weight is only 52kg, while ensuring a larger range of motion and faster cycle time. In a word, Epson c8l robot is specially used for heavy work in narrow space. Our goal is to continue to develop durable and compact 6-axis robots that meet Epson’s high performance standards. The new Epson c8l robot increases the load to 8kg, so as to complete more work, while ensuring fast speed, short cycle time and small floor area.

Epson C8L robot only needs 0.38 second cycle time (load up to 3kg). It uses a 1000W motor on the J1 axis to start, which is powerful but compact. The range of motion is larger than the floor area, and has a high degree of flexibility.

• Fast cycle time, easy movement

• Innovative residual vibration control technology developed by Epson (see features / advantages page)

• Greater range of motion

• Slim linear design for greater flexibility

• ISO class 3 clean / antistatic and protective (IP67)

C8 robot has a slender linear body and a compact wrist, and has a larger range of motion and less mechanical restrictions. Bigger motor and excellent servo controller make its speed faster, motion control more accurate and motion more stable in the next application. In addition, Epson innovatively developed a high-performance servo system. The acceleration / deceleration performance of the robot can make it move faster on a smooth path.

Epson innovative development: Aftervibration technology — most 6-axis robot manufacturers need to expand the size to achieve the rigidity required for excellent performance. Epson’s aftervibration technology enables the slender linear arm to produce high speed, accuracy and acceleration / deceleration performance. Vibration reduction is the key to achieve high performance. The residual vibration technology adopts Epson quartz micromotor system sensor, and greatly reduces the vibration by detecting and eliminating the vibration.

Epson C8L long-distance 6-axis robot is very suitable for a wide range of applications in automotive, medical, electronic products, electrical appliances, consumer goods, food, computer peripherals, semiconductors, plastics and aerospace industries, including automotive component handling, industrial component handling or consumer product assembly. The robot can be used in a large number of scenes. In the next application, please contact us for help.

Based on the successful experience of C4 robot, Epson C8 robot maintains the key slim linear design and C4 robot’s high performance, high load and larger operating distance.Suitable for different applications requiring high flexibility, high speed and small footprint. Epson C8L long-distance 6-axis robot uses power driven servo technology to achieve the high-performance results expected by customers. In addition, by using the cutting-edge residual vibration technology, namely Epson quartz micro electromechanical system, which can sense the angular velocity and feed it back to the servo motion system, C8 series robots can greatly reduce the vibration in the process of motion and start / stop, making the motion more stable and positioning faster.

• High speed cycle time

• Small footprint and light weight

• Load up to 8kg and short cycle time

• High repeat positioning accuracy, in line with customer expectations

• Residual vibration technology ensures fast movement and positioning

• The floor area is small to ensure the utilization rate of plant space

• Light weight, easy for ceiling / sidewall installation and track / slide installation

• The compact wrist provides class leading fifth joint mobility

• Excellent range of motion

• Wide first joint (+ / – 240 degrees) working range (about 30% more than traditional 6-axis robot)

• Suitable for loading / unloading in limited or narrow space

• Epson RC + software is at the forefront of the industry in terms of ease of use and saving development time

• RC700-a controller provides high performance at low cost

• Integration options optimize system performance and reduce total development time (see options page for more information)

• High performance and fast processing capability

• Customers can use their own PC to connect with RC700 controller, and get better performance at lower cost

• Visual guidance

• Network connection with RC + 7.0 API

• Device network, fieldbus, Ethernet, IP, Ether CAT, CC link fieldbus connection

• GUI Builder – easy to create GUI through Epson RC + robot development environment

• Other axis controls

• Belt tracking

• Clean / antistatic

• The IP67 model is available

• Automobile

• Medical

• Consumer products

• Electronic products

• Industrial products

• Laboratory automation

• Communication

• Pharmaceutical

• Semiconductor

| Model: C8 | |

| Core specifications | Repeat positioning accuracy: +/-0.02mm |

| Load (kg): Max 8 / Rated 3 | |

| Cycle time: 0.31 sec(1Kg Load) | |

| Weight: 49 kg (53kg IP67) | |

| Arm length | Horizontal working distance (to mounting surface): 791mm |

| Horizontal working distance (to wrist Center): 711mm | |

| Other arm length configuration | Installation type: Table, Ceiling |

| Clean type and Antistatic type: ISO 3 and Antistatic | |

| Protection type: IP67 rated | |

| Subscriber line | Wire: 15 pin (D-sub connector) |

| Ethernet: 8-pin RJ45 (class 5 or equivalent) | |

| Guide force connection: guide force connector 6 pin (Future) | |

| Air: 2 (6mm) | |

| Environmental applicability | Temperature: 5- 40 ℃ |

| Humidity: 10 – 80% (non condensing) | |

| Safety standards | CE |

| JIS B 8433 | |

| ANSI/RIA R15.06-1999 | |

| Mechanical instructions | EN ISO 12100-1、EN ISO 12100-2、EN ISO 10218、EN 60204-1、EN ISO 13849-1 |

| EMC directive | EN55011、EN61000-6-2 |

| JIS B 8433-1 | |

| CE | |

| In line with KC mark | |

| RoHS directive、REACH | |

| Available controllers | RC700-A– PC driven high performance controller |

| RC700DU-A- multi robot control drive unit | |

| Range of motion | J1 (Steering): +/- 240° |

| J2 (Lower Arm): -158to +65° | |

| J3 (Upper Arm): -61 to +202° | |

| J4 (Wrist Roll): +/-200° | |

| J5 (Wrist Bend): +/-135° | |

| J6 (Wrist Twist): +/-360° | |

| Motor Wattage | J1: 1000 W |

| J2: 750 W | |

| J3: 400 W | |

| J4: 100 W | |

| J5: 100 W | |

| J6: 100 W | |

| Allowable moment of inertia | J4:0.47 kg•m2 |

| J5:0.47 kg•m2 | |

| J4:0.15 kg•m2 | |

| Braking | All 6 axes |

| Options | Visual guidance (CV2 or PV1) |

| Net support (Epson RC + 7.0 API) | |

| Device network, Ethernet / IP, Fieldbus, EtherCAT, CC link | |

| Belt tracking | |

| GUI construction | |

| Pressure sensing | |

| Robot cable | 3M (Standard), 5m (Optional), 10m (Optional) |

| Software | EPSON RC+ 7.0 |

Used for a Wide Variety of Applications and Industries

Automotive

Medical

Consumer Products

Electronics

Industrial Products

Lab Automation

Telecommunications

Pharmaceutical

Semiconductor

After-Sales Service: Online Services and Video technical