FANUC robots are used in factories around the globe to help manufacturers improve quality, increase capacity and overcome skills shortages. Robots build products too intricate for human hands to assemble, prepare pharmaceuticals in aseptic conditions and protect workers from dangerous or harmful environments. Automated robotic systems benefit manufacturers of every scale and in every industry. FANUC has a wide range of robot types and models available for various applications. Various features are available for FANUC robots to make a maximum use of robot flexibilities.

Robotic systems can be complex, demanding a deep understanding of industrial robotics technology and extensive integration experience. This is where Dr. Industrial excels. FANUC industrial robots are some of the most sophisticated robots in the world, and Dr. Industrial puts them to work. FANUC is an automation company specializing in advanced robotic arms for manufacturing. FANUC robots incorporate state-of-the-art technologies, like 3D vision systems and force sensing, to take on an almost every manufacturing task imaginable. With more than 100 models, FANUC has a solution for every task, ranging from compact five- and six-axis articulated robots to huge machines with long reach and massive payload capabilities. These options include painting robots, high-speed “delta” robots, and the CR-35iA “collaborative” robot that needs no guarding.

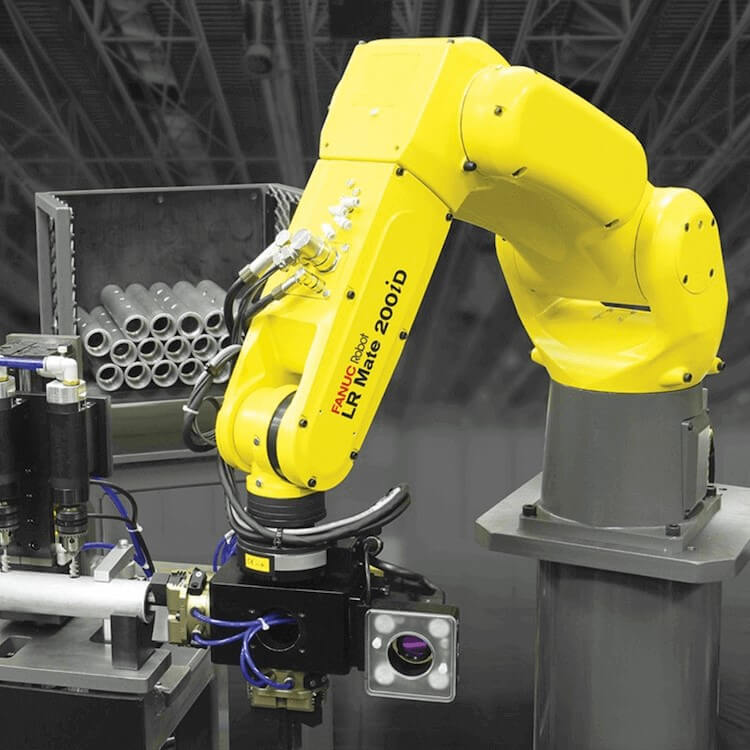

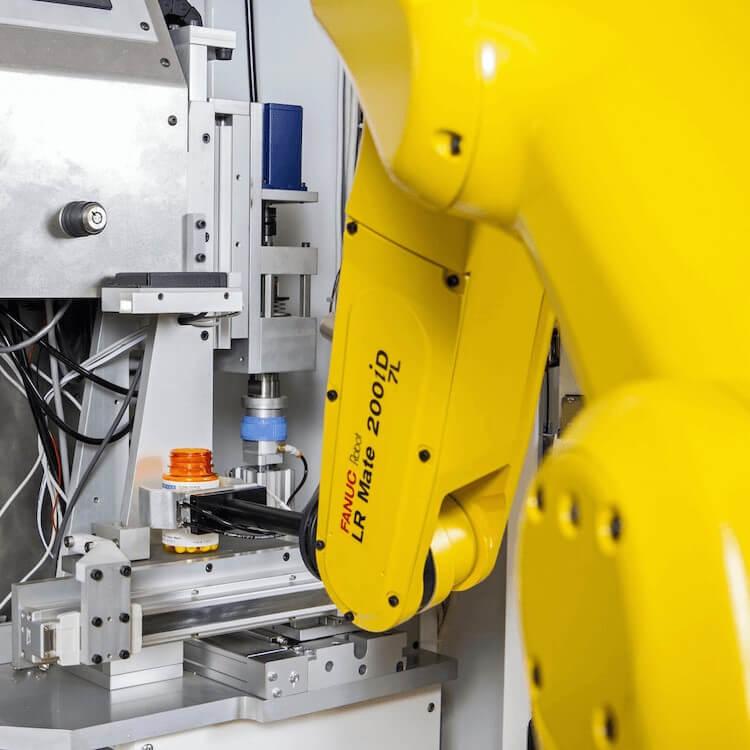

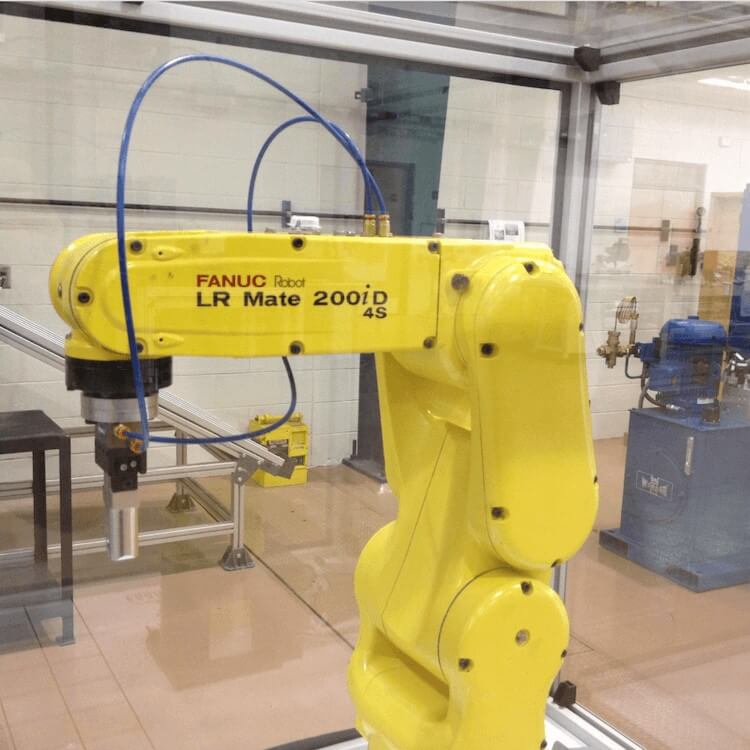

LR Mate 200iD is a human arm sized mini robot.

● The slim arm minimizes interference to peripheral equipment at narrow space.

● Standard arm (717mm reach), short arm (550mm reach), long arm (911mm reach), clean type, water-proof type for washing and 5 axes high speed type are available.

● The lightest mechanical unit in its class realizes easy integration into a machine or upside-down mounting on a frame.

● High rigidity arm and the most advanced servo technology enable smooth motion without vibration in high speed operation.

● Wrist load capacity is enhanced extremely. It makes efficiency to increase by handling plural work pieces.

● Sensor cable, auxiliary axis cable, solenoid valve, air tube and I/O cable for device control are integrated in the arm. It realizes easy hand cabling. (option for limited model)

● Dust and water proof ability is enhanced to IP69K for mechanical unit. It expands various application. (option for limited model)

● Various intelligent functions are available as option, such as “robot link” that synchronizes plural robots operation, “soft float” that enables the hand to follow the work piece and“collision detection”that minimizes damage by interference to peripheral equipment.

● Advanced intelligent functions are available as an option, such as iRVision (integrated vision) and part insertion by force sensor.

| DESCRIPTION | ||

| Product name | ||

| Model | LR Mate 200iD | |

| Controlled axes | 6 | |

| Reach | 717mm | |

| Installation | Floor/Upside-down ,Angle mount | |

| Motion range | J1 | 340°/360° 5.93rad/6.28rad |

| J2 | 245° 4.28rad | |

| J3 | 420° 7.33rad | |

| J4 | 380° 6.63rad | |

| J5 | 250° 4.36rad | |

| J6 | 720° 12.57rad | |

| Max. load capacity at wrist | 7kg | |

| Allowable load moment at wrist | J4 | 16.6N.m |

| J5 | 16.6N.m | |

| J6 | 9.4N.m | |

| Allowable load inertia at wrist | J4 | 0.47kg.m2 |

| J5 | 0.47kg.m2 | |

| J6 | 0.15kg.m2 | |

| Repeatability | ±0.01mm | |

| Mass | 25kg | |

Suitable for these applications

Arc welding/Assembly/Cutting/Separation/Handling/Measuring/Inspection/Palletizing/ Packaging

After-Sales Service: Online Services and Video technical